旋 筒 阀/ Rotor type valve

一、概述/ Summary:

HD9P(E/HY)90H(X) 旋筒阀是汉德股份经过多年市场调研并开发的一种多功能新型阀门,可用于介质高性能调节、切断、分流和换向等,具有球阀、三通及多通、蝶阀、旋塞阀、调节阀等多种应用功能,广泛应用于煤化工、冶金、石化、电力、轻工、医药及军工等行业,汉德股份于2015年取得多项国家专利,系全球阀门行业首创。

旋筒阀是一种阀芯形状为一圆柱筒形,圆柱面上开有过流窗口,通过旋转阀芯方式开启和关闭阀门,起到截流或调节作用。适用各种工况,有着特殊的优势和长处。旋筒阀已经解决了传统的调节阀所遇到的一些问题,而且部分已超出了传统调节阀的性能。

Rotor type valve is hande shares after years of market research and development of a multi function valve, for medium and high performance and regulation, cut, split and commutation. With a ball valve, three-way and multi pass, butterfly valve, plug valve, regulating valve and other applications, widely used in coal chemical industry, metallurgy, petrochemical, power, light industry, medicine and military industries, hande shares in 2015 made a number of national patents, the Department of the world's valve industry first.

Rotor type valve is a valve core shape for a cylindrical shell, cylindrical surface has over the flow of the window, through the rotary valve to open and close the valve, play the role of closure or regulation. Applicable to all kinds of conditions, has a special advantage and strength. Rotor type valve has solved some of the problems encountered by the traditional control valve, and the part has been beyond the traditional control valve performance.

二、结构及材质/ Structure and material:

三、特点/ Characteristic:

四、分类/ Classification

根据不同工况,旋筒阀选用不同的控制元件,可以分类如下:

According to different working conditions, rotary cylinder valve selection of different control components, can be classified as follows:

A、全通型:主要用于切断要求的场合。在管道系统中起对介质的接通或截流,流通能力强,压损小,双向密封可达到零泄漏。

All pass: mainly used for cutting applications. In the pipe system, the medium is connected or cut, the flow capacity is strong, the pressure loss is small, the two-way sealing can achieve zero leakage.

B、调节型:主要用于调节要求的场合(大可调比)。在管道系统中主要起调节作用,阀门执行机构接收到控制信号。带动阀筒作旋转运动,转动作角度与控制信号成线性关系,从而控制管道中工艺参数的目的。流道口可按需要定制成线性、等百分比或一些特殊形状从而获得不同性能的流量曲线。

Adjustable type: mainly used to adjust the requirements of the occasion (adjustable ratio). In the pipe system, the main function of the valve actuator to receive control signal. Drive valve cylinder for rotary motion, rotation angle and control signal linear relationship, so as to control the process parameters in the pipeline. The flow rate can be customized according to the need to be linear, equal percentage or some special shape to obtain different performance of the flow curve.

C、 三通或多通(调节)型:L型、T型。三通型旋筒阀是指阀体有三个进出口,三通旋筒阀分为L型和T型两种,L型主要用于介质的换向,介质的流向从一根管道换为另一根管道。T型主要用于介质的分流和合流,分流是控制一种介质分别从不同的管道流出,合流是控制两种介质汇合于一根管道。

多通型旋筒阀是指垂直于执行器的旋转轴平面上有四个或以上进出口,或在该平面的下端也有一个出口,该阀的作用主要用于两种以上介质的换向或汇合于一根管道。

Three way or multi pass (regulation) type: L type, T type. Three way type of rotary valve is the valve body has three import and export, the three valve is divided into L type and T type two, L type is mainly used for the medium of the direction of the flow from one pipe to another. T type is mainly used for the medium flow and confluence, the diversion is to control the flow of a medium separately from the different pipe, the confluence is the control of the two media convergence in a pipeline.

Multi type rotary cylinder valve refers to the vertical axis of the actuator on the axis of the plane has four or more of the import and export, or in the lower end of the plane also have an outlet, the role of the valve is mainly used for more than two medium or a pipe.

D、 降噪型:能有效降低噪声。介质在管道中流通,一定的条件下会产生大的噪声,会对设备产生损坏,对环境造成污染。因此在阀内件设计采取一些降噪措施可降低噪声。

Noise reduction type: can effectively reduce the noise. Medium in the pipe flow, certain conditions will produce large noise, will cause damage to the equipment, environmental pollution. Therefore in the valve design to take some noise reduction measures can reduce the noise

E、小流量型:当介质的流量很微小时,阀门很小的开度就达到了流量要求,因此无法正常调节,此时可将节流口形状设计为最小1mm宽的矩型窗口,流量特性为线性,Cv值可达到极小,从而提高了微小流量时的控制精度。

Small flow type: when the medium flow is very small, the valve is very small opening to meet the flow requirements, and therefore can not be adjusted, this time can be the throttle orifice shape design for the minimum 1mm wide window, flow characteristics for linear, Cv value can reach a minimum, so as to improve the control accuracy of micro flow.

F、反汽蚀型:汽蚀是材料在液体的压力和温度达到临界值时产生的一种破坏形式,汽蚀分为闪蒸和空化两个阶段。管道中的液体在一定的条件下,部分液体气化成气体状态,产生气泡,形成气液两相流这就是闪蒸过程。阀下游的压力升高,压破气泡的过程即空化过程。汽蚀可使阀内件的表面产生磨痕、深沟及凹坑。阀一般采用曲折路径、多级降压、多孔节流及引导介质流向阀体中心区防止冲击阀体内壁的方式来防止和降低汽蚀的破坏。

The anti cavitation, cavitation is material in the pressure and temperature of the liquid reaches critical values produced a failure mode, cavitation is divided into two stages, such as flashing and cavitation. The liquid in the pipeline under certain conditions and partially vaporizes into gas state, bubble, formation of gas-liquid two-phase flow which is the process of flash. Downstream of the valve's pressure increases, the cavitation bubble crush process process. Cavitation can make the surface trim have worn, and deep pits. Valve is generally used in a tortuous path, multi-stage pressure, porous throttle and guide the flow of the valve body center to prevent the impact of the inner wall of the valve body to prevent and reduce the damage of cavitation.

G、多级降压降噪型:当介质在管道中流过后噪声级别相当高时,也可通过多级降压降噪的方式来解决。

Multi-stage buck noise reduction type: when the medium flow through the pipe in the pipe is quite high, it can be resolved through the multi-level buck.

H、半筒型:当介质中含有固体棵粒或纤维状物质时,可选用半筒型结构,此种结构具有自洁及剪切功能。

Half tube type: when the medium containing solid particles or fibrous material, can choose a half tube type structure, this structure has the clean and shear function.

K、角式旋筒阀:

主要用于一些高压差或流阻小的工况,也可作为釜底放料阀使用。特别适合于煤化工行业中的黑水和灰水的压力和流量调节。

角式旋筒阀的阀芯与阀座的材料经过精加工而制成,表面粗糙度达到Rc0.04,材料硬度达到HRA90以上极耐磨。传统的黑水调节阀采用文丘里角式直行程结构,流向为高进低出,启闭力量大,阀杆上下动作,因阀杆与导向套之间有间隙,容易产生振荡出象,经常阀芯从根部折断,用了一段时间后,阀杆上容易结垢,致使阀芯无法动作。而角式旋筒阀为角行程动作,旋转扭矩小,在转动过程中具有自洁功能,筒式阀芯与阀体之间接触面积大而均匀,解决了传统角式座阀的振动与爬行现象,阀芯与阀座之间镜面接触,保证了密封的可靠性,从而提高了调节精度。

Mainly used for high pressure or flow resistance of the working conditions, but also can be used as the bottom discharge valve. The pressure and flow is particularly suitable for the coal chemical industry in the black and gray water regulation.

The valve core and valve seat of the valve core and valve seat material after finishing, the surface roughness reached Rc0.04, the material hardness of the HRA90 more than a very abrasive. Traditional black water regulating valve adopts venturi angle type straight stroke structure, the flow of high into a low, opening and closing force, stem moves up and down, there is a gap between the stem and the guide sleeve, prone to oscillate like, often the spool from the roots broken, a period of time, the stem is easy to scale, resulting in the spool can not action. The angle rotary cylinder valve for angular stroke, rotary torque is small, in the process of rotation with the self clean function, cylinder type valve body with large contact area between large and uniform, to solve the traditional angle seat valve vibration and crawling phenomenon, the valve core and valve seat contact between the valve and the valve to ensure the reliability of the sealing, thereby improving the accuracy of adjustment.

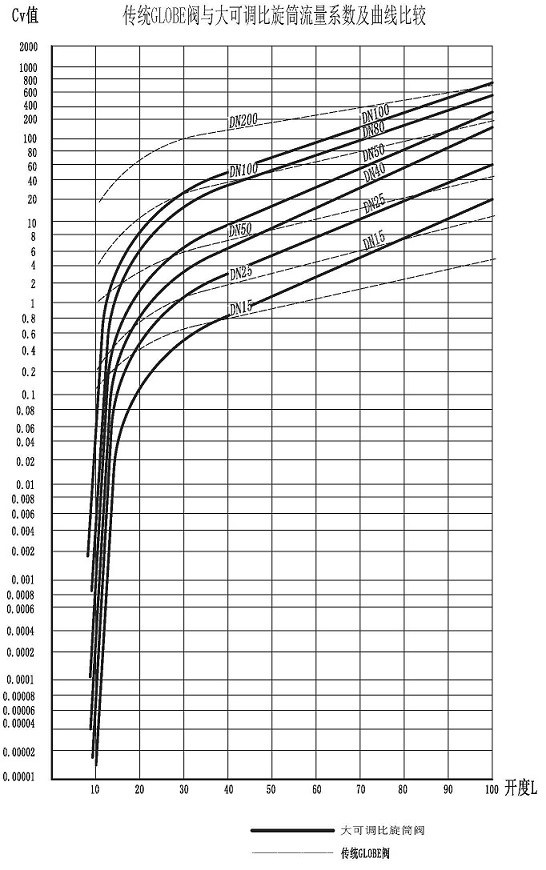

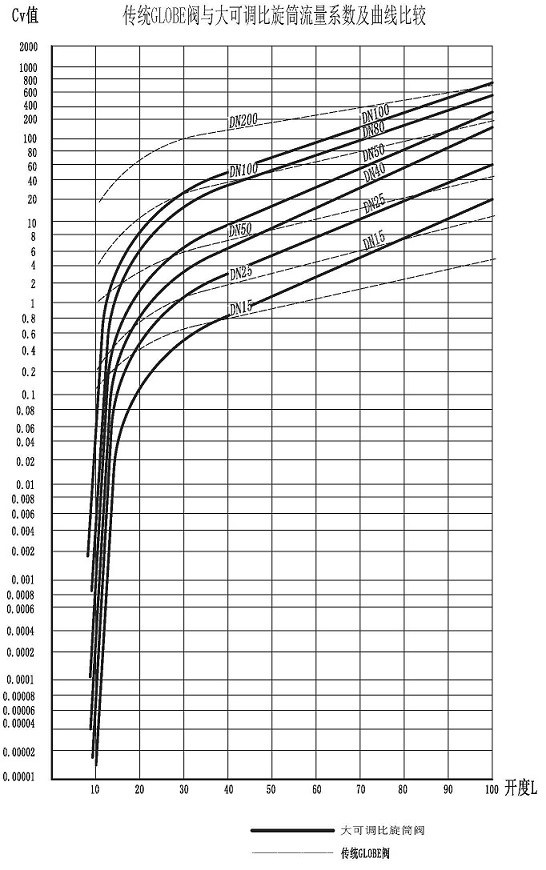

五、流量系数曲线对比/ Flow coefficient curve comparison

六、主要技术性能/ Main technical performance:

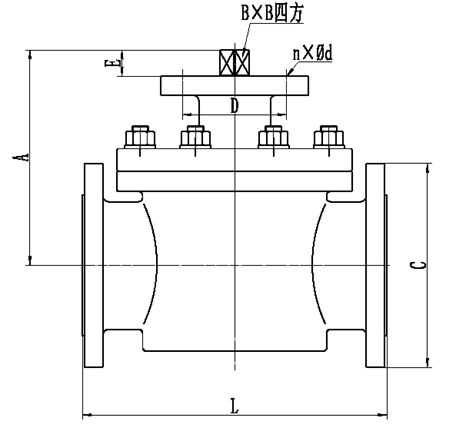

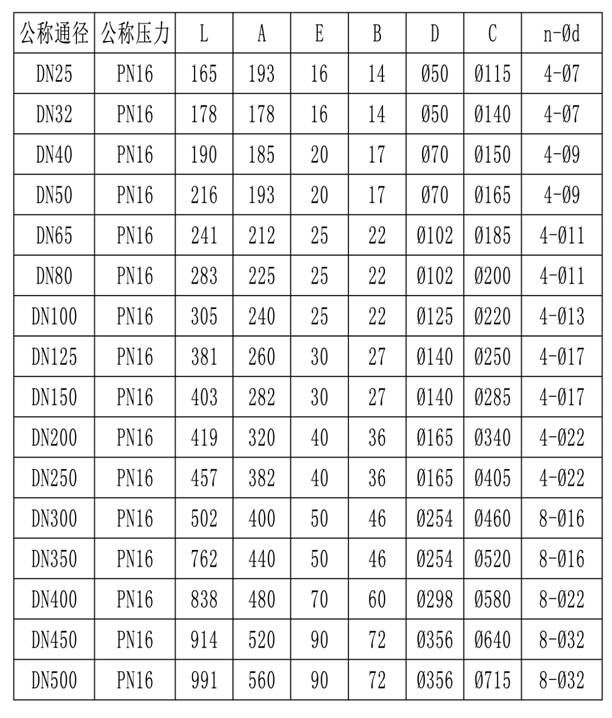

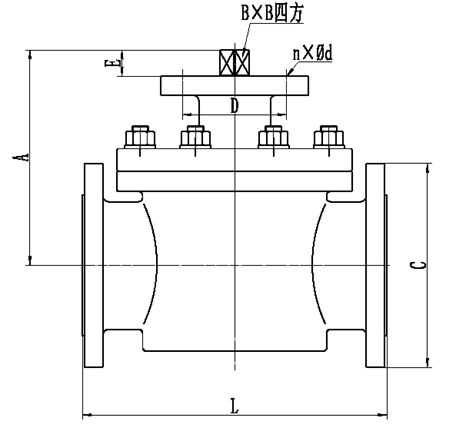

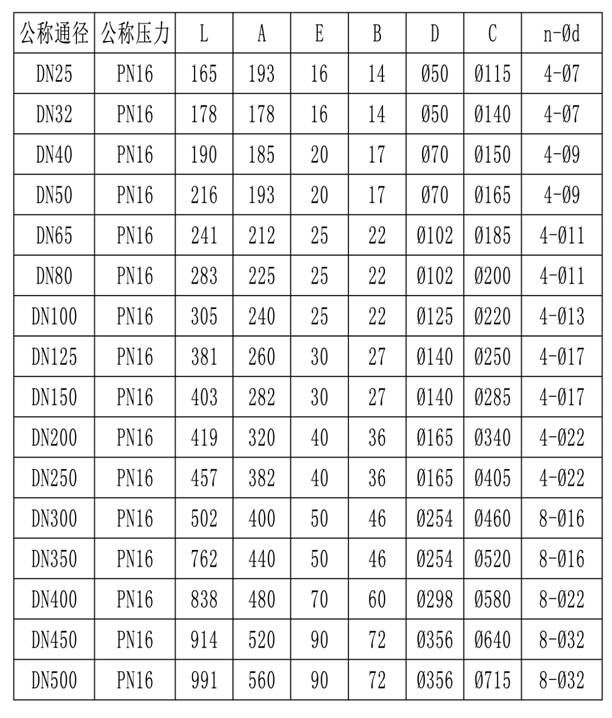

七、外形及连接尺寸/ Shape connection size:

备注:角式旋筒阀和三通及多通旋筒阀的尺寸具体见相关小样图。

八、额定Cv:

*以上Cv值为最基本型的旋筒阀的额定Cv值,多级降噪、多级降压式旋筒阀的额定Cv值根据现场工艺参数经计算后确定,同口径的旋筒阀也可选用低于基本型的额定Cv值,具体Cv值的大小经计算后确定。

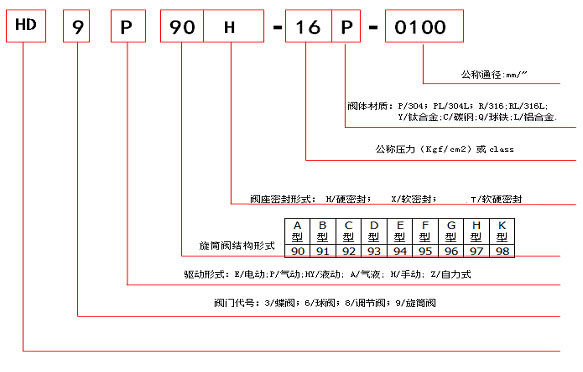

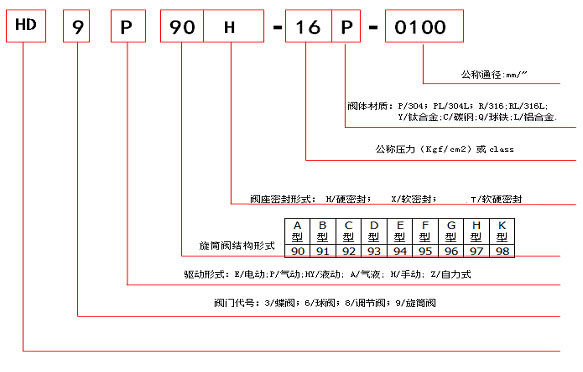

九、汉德旋筒阀型号编制/ Hande Model establishment of Rotor type valve

2、流量特性;执行机构型号;供气压力;

3、阀作用形式(气开or气关)

4、附件要求(定位器、减压阀、手轮等)

5、正常流量和要求最大流量;

6、介质名称、温度、比重、压力(对应最大or最小流量时的)

7、介质粘度,是否有悬浊液,浓度,颗粒大小)。

ordering information: (see table three: data sheet)

1, type; nominal diameter * valve seat diameter; nominal pressure; flange connection form;

2, flow characteristics; the implementation of the model; gas pressure;

3, valve action form (gas or gas)

4, annex requirements (locator, valve, hand wheel, etc.)

5, normal flow and maximum flow rate;

6, the media name, temperature, specific gravity, pressure (corresponding to the maximum or minimum flow)

7, whether the suspension, medium viscosity, concentration, particle size).

一、概述/ Summary:

HD9P(E/HY)90H(X) 旋筒阀是汉德股份经过多年市场调研并开发的一种多功能新型阀门,可用于介质高性能调节、切断、分流和换向等,具有球阀、三通及多通、蝶阀、旋塞阀、调节阀等多种应用功能,广泛应用于煤化工、冶金、石化、电力、轻工、医药及军工等行业,汉德股份于2015年取得多项国家专利,系全球阀门行业首创。

旋筒阀是一种阀芯形状为一圆柱筒形,圆柱面上开有过流窗口,通过旋转阀芯方式开启和关闭阀门,起到截流或调节作用。适用各种工况,有着特殊的优势和长处。旋筒阀已经解决了传统的调节阀所遇到的一些问题,而且部分已超出了传统调节阀的性能。

Rotor type valve is hande shares after years of market research and development of a multi function valve, for medium and high performance and regulation, cut, split and commutation. With a ball valve, three-way and multi pass, butterfly valve, plug valve, regulating valve and other applications, widely used in coal chemical industry, metallurgy, petrochemical, power, light industry, medicine and military industries, hande shares in 2015 made a number of national patents, the Department of the world's valve industry first.

Rotor type valve is a valve core shape for a cylindrical shell, cylindrical surface has over the flow of the window, through the rotary valve to open and close the valve, play the role of closure or regulation. Applicable to all kinds of conditions, has a special advantage and strength. Rotor type valve has solved some of the problems encountered by the traditional control valve, and the part has been beyond the traditional control valve performance.

二、结构及材质/ Structure and material:

| 序号 | 名称/ Name | 材质/material |

| 1 | 阀体/Body | WCB、CF8、CF3等 |

| 2 | 阀座/ Seat | SS304、SS304+PTFE、WC等 |

| 3 | 阀芯/ Spool | SS304+STL、WC等 |

| 4 | 阀盖/ bonnet | WCB、CF8、CF3 |

| 5 | 阀座压盖/ Seat Gland |

SS304、SS316 |

| 6 | 密封垫/ A seal | PTFE、金属缠绕垫 |

| 7 | 压缩弹簧/Spring |

SS304、17-7PH、Inconel |

| 8 | 执行机构/ actuator | 气动活塞式、电动、液动 |

三、特点/ Characteristic:

- 具有超大可调比,可调比可达到10000:1。

- 全开状态零压降。

- 极高的Cv值(是传统Globe阀的四倍以上),所以相等额定Cv值下,可选用更小口径阀门。

- 启闭力矩小(相同口径球阀的三分之一左右),阀门启闭无起跳、无爬行,力矩均衡,动作灵敏。

- 压损很小,节约能耗。

- 结构简单,可实现在线维修。

- 低噪音抗气蚀。

- 适用于不同的介质与流体:气体、蒸汽、悬浮液、结晶、纤维物等。

- 可360度任意位置安装。

- grees can be installed at any position。

- 对称性的设计,液体流向可任意选择。

- 重量轻,体积小。

- 双向密封,可选用多种形式阀座,密封性能好,可靠性高。

- 填料寿命长,不容易外漏。

- 剪切性能好。适用纤维状介质,和诸如焊渣等硬度颗粒。

- 防堵性能好。

- 适用范围广。通径从小到几毫米到几米,从高真空到高压力均可应用。

四、分类/ Classification

根据不同工况,旋筒阀选用不同的控制元件,可以分类如下:

According to different working conditions, rotary cylinder valve selection of different control components, can be classified as follows:

A、全通型:主要用于切断要求的场合。在管道系统中起对介质的接通或截流,流通能力强,压损小,双向密封可达到零泄漏。

All pass: mainly used for cutting applications. In the pipe system, the medium is connected or cut, the flow capacity is strong, the pressure loss is small, the two-way sealing can achieve zero leakage.

B、调节型:主要用于调节要求的场合(大可调比)。在管道系统中主要起调节作用,阀门执行机构接收到控制信号。带动阀筒作旋转运动,转动作角度与控制信号成线性关系,从而控制管道中工艺参数的目的。流道口可按需要定制成线性、等百分比或一些特殊形状从而获得不同性能的流量曲线。

Adjustable type: mainly used to adjust the requirements of the occasion (adjustable ratio). In the pipe system, the main function of the valve actuator to receive control signal. Drive valve cylinder for rotary motion, rotation angle and control signal linear relationship, so as to control the process parameters in the pipeline. The flow rate can be customized according to the need to be linear, equal percentage or some special shape to obtain different performance of the flow curve.

C、 三通或多通(调节)型:L型、T型。三通型旋筒阀是指阀体有三个进出口,三通旋筒阀分为L型和T型两种,L型主要用于介质的换向,介质的流向从一根管道换为另一根管道。T型主要用于介质的分流和合流,分流是控制一种介质分别从不同的管道流出,合流是控制两种介质汇合于一根管道。

多通型旋筒阀是指垂直于执行器的旋转轴平面上有四个或以上进出口,或在该平面的下端也有一个出口,该阀的作用主要用于两种以上介质的换向或汇合于一根管道。

Three way or multi pass (regulation) type: L type, T type. Three way type of rotary valve is the valve body has three import and export, the three valve is divided into L type and T type two, L type is mainly used for the medium of the direction of the flow from one pipe to another. T type is mainly used for the medium flow and confluence, the diversion is to control the flow of a medium separately from the different pipe, the confluence is the control of the two media convergence in a pipeline.

Multi type rotary cylinder valve refers to the vertical axis of the actuator on the axis of the plane has four or more of the import and export, or in the lower end of the plane also have an outlet, the role of the valve is mainly used for more than two medium or a pipe.

D、 降噪型:能有效降低噪声。介质在管道中流通,一定的条件下会产生大的噪声,会对设备产生损坏,对环境造成污染。因此在阀内件设计采取一些降噪措施可降低噪声。

Noise reduction type: can effectively reduce the noise. Medium in the pipe flow, certain conditions will produce large noise, will cause damage to the equipment, environmental pollution. Therefore in the valve design to take some noise reduction measures can reduce the noise

E、小流量型:当介质的流量很微小时,阀门很小的开度就达到了流量要求,因此无法正常调节,此时可将节流口形状设计为最小1mm宽的矩型窗口,流量特性为线性,Cv值可达到极小,从而提高了微小流量时的控制精度。

Small flow type: when the medium flow is very small, the valve is very small opening to meet the flow requirements, and therefore can not be adjusted, this time can be the throttle orifice shape design for the minimum 1mm wide window, flow characteristics for linear, Cv value can reach a minimum, so as to improve the control accuracy of micro flow.

F、反汽蚀型:汽蚀是材料在液体的压力和温度达到临界值时产生的一种破坏形式,汽蚀分为闪蒸和空化两个阶段。管道中的液体在一定的条件下,部分液体气化成气体状态,产生气泡,形成气液两相流这就是闪蒸过程。阀下游的压力升高,压破气泡的过程即空化过程。汽蚀可使阀内件的表面产生磨痕、深沟及凹坑。阀一般采用曲折路径、多级降压、多孔节流及引导介质流向阀体中心区防止冲击阀体内壁的方式来防止和降低汽蚀的破坏。

The anti cavitation, cavitation is material in the pressure and temperature of the liquid reaches critical values produced a failure mode, cavitation is divided into two stages, such as flashing and cavitation. The liquid in the pipeline under certain conditions and partially vaporizes into gas state, bubble, formation of gas-liquid two-phase flow which is the process of flash. Downstream of the valve's pressure increases, the cavitation bubble crush process process. Cavitation can make the surface trim have worn, and deep pits. Valve is generally used in a tortuous path, multi-stage pressure, porous throttle and guide the flow of the valve body center to prevent the impact of the inner wall of the valve body to prevent and reduce the damage of cavitation.

G、多级降压降噪型:当介质在管道中流过后噪声级别相当高时,也可通过多级降压降噪的方式来解决。

Multi-stage buck noise reduction type: when the medium flow through the pipe in the pipe is quite high, it can be resolved through the multi-level buck.

H、半筒型:当介质中含有固体棵粒或纤维状物质时,可选用半筒型结构,此种结构具有自洁及剪切功能。

Half tube type: when the medium containing solid particles or fibrous material, can choose a half tube type structure, this structure has the clean and shear function.

K、角式旋筒阀:

主要用于一些高压差或流阻小的工况,也可作为釜底放料阀使用。特别适合于煤化工行业中的黑水和灰水的压力和流量调节。

角式旋筒阀的阀芯与阀座的材料经过精加工而制成,表面粗糙度达到Rc0.04,材料硬度达到HRA90以上极耐磨。传统的黑水调节阀采用文丘里角式直行程结构,流向为高进低出,启闭力量大,阀杆上下动作,因阀杆与导向套之间有间隙,容易产生振荡出象,经常阀芯从根部折断,用了一段时间后,阀杆上容易结垢,致使阀芯无法动作。而角式旋筒阀为角行程动作,旋转扭矩小,在转动过程中具有自洁功能,筒式阀芯与阀体之间接触面积大而均匀,解决了传统角式座阀的振动与爬行现象,阀芯与阀座之间镜面接触,保证了密封的可靠性,从而提高了调节精度。

Mainly used for high pressure or flow resistance of the working conditions, but also can be used as the bottom discharge valve. The pressure and flow is particularly suitable for the coal chemical industry in the black and gray water regulation.

The valve core and valve seat of the valve core and valve seat material after finishing, the surface roughness reached Rc0.04, the material hardness of the HRA90 more than a very abrasive. Traditional black water regulating valve adopts venturi angle type straight stroke structure, the flow of high into a low, opening and closing force, stem moves up and down, there is a gap between the stem and the guide sleeve, prone to oscillate like, often the spool from the roots broken, a period of time, the stem is easy to scale, resulting in the spool can not action. The angle rotary cylinder valve for angular stroke, rotary torque is small, in the process of rotation with the self clean function, cylinder type valve body with large contact area between large and uniform, to solve the traditional angle seat valve vibration and crawling phenomenon, the valve core and valve seat contact between the valve and the valve to ensure the reliability of the sealing, thereby improving the accuracy of adjustment.

五、流量系数曲线对比/ Flow coefficient curve comparison

六、主要技术性能/ Main technical performance:

| 序号 | 类别/ Category | 参数和性能 | 序号 | 类别/ Category | 参数和性能 |

| 1 | 公称通径/ body size | 1”-20”/DN25-DN500 | 8 | 驱动方式/ actuator | 气动、电动、液动 |

| 2 | 压力等级/ Press.Rating | Class150-class900/ PN20-PN160 |

9 | 流量特性/ Flow characteristics | 线性、等百分比 |

| 3 | 适用介质/state | 水、油、气、煤浆等 | 10 | 执行机构/ Executing agency | 气缸、电动头、液动 |

| 4 | 适用温度/Temp.℃ | -100-650℃ | 11 | 附件/ Annex | 减压阀、过滤器、定位器等 |

| 5 | 泄漏等级/Seat Leakage Classs | ANSI CLASS ⅤⅥ | 12 | 阀体/Body | WCB、CF8、CF8M等 |

| 6 | 连接方式/Conn.Type | 法兰、焊接 | 13 | 阀内件/ Spool | SS304、SS316、SS316L等 |

| 7 | 结构形式/Structure form | 直通或角式 | 14 | 可调比/ Adjustable ratio | 10000:1 |

七、外形及连接尺寸/ Shape connection size:

备注:角式旋筒阀和三通及多通旋筒阀的尺寸具体见相关小样图。

八、额定Cv:

| 公称通径 | DN25 | DN32 | DN40 | DN50 | DN65 | DN80 | DN100 | DN125 | DN150 | DN200 | DN250 | DN300 |

| 额定Cv (快开) | 100 | 146 | 237 | 384 | 531 | 714 | 1315 | 2030 | 3122 | 4694 | 6660 | 8760 |

| 额定Cv (大可调比) | 100 | 146 | 237 | 384 | 531 | 714 | 1315 | 2030 | 3122 | 4694 | 6660 | 8760 |

| 额定Cv (等百分比) | 84 | 122 | 198 | 320 | 443 | 595 | 1096 | 1692 | 2602 | 3912 | 5550 | 7300 |

| 额定Cv (线性) | 86 | 125 | 205 | 330 | 453 | 605 | 1105 | 1710 | 2710 | 4020 | 5750 | 7400 |

九、汉德旋筒阀型号编制/ Hande Model establishment of Rotor type valve

- 订货须知:(见附表三:数据表)

2、流量特性;执行机构型号;供气压力;

3、阀作用形式(气开or气关)

4、附件要求(定位器、减压阀、手轮等)

5、正常流量和要求最大流量;

6、介质名称、温度、比重、压力(对应最大or最小流量时的)

7、介质粘度,是否有悬浊液,浓度,颗粒大小)。

ordering information: (see table three: data sheet)

1, type; nominal diameter * valve seat diameter; nominal pressure; flange connection form;

2, flow characteristics; the implementation of the model; gas pressure;

3, valve action form (gas or gas)

4, annex requirements (locator, valve, hand wheel, etc.)

5, normal flow and maximum flow rate;

6, the media name, temperature, specific gravity, pressure (corresponding to the maximum or minimum flow)

7, whether the suspension, medium viscosity, concentration, particle size).

旋筒阀|旋塞阀|旋转阀|滚筒阀|三通阀换向阀|降噪阀门|小流量阀门|多级降压阀|角型旋筒式黑水调节阀|旋筒黑水角阀|旋筒黑水调节阀|角式旋筒阀|黑水调节阀|灰水调节阀|釜底放料阀| 煤化工阀门|分流换向阀|流量调节阀